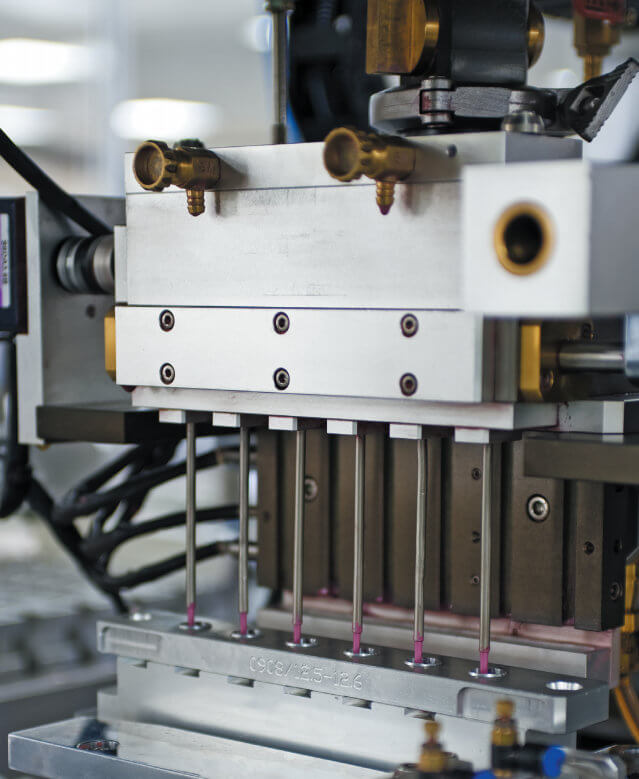

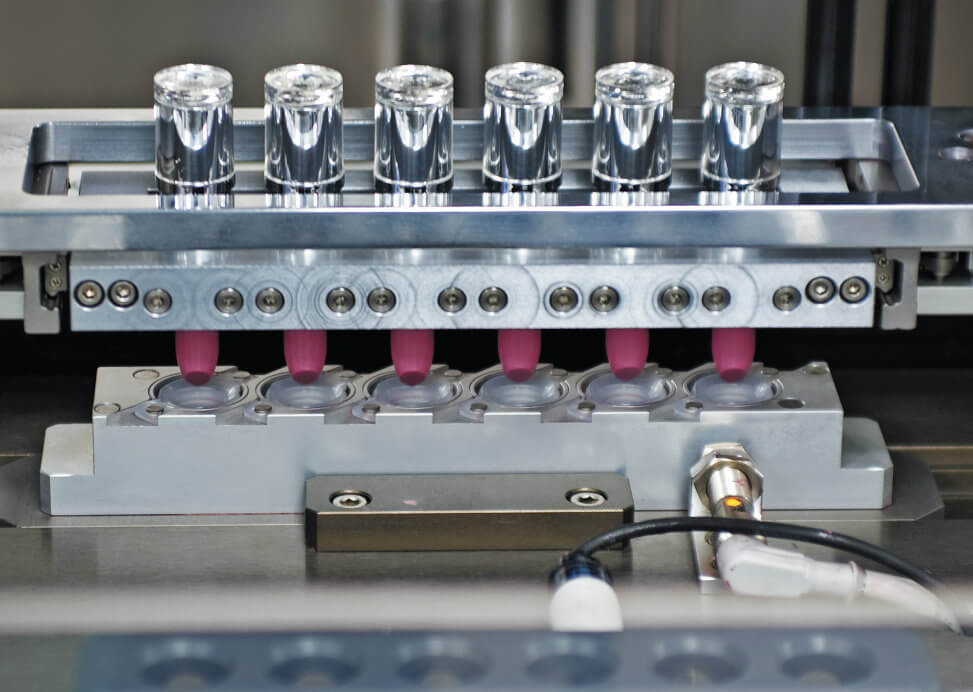

The Faberlic production facility covers more than 45,000 square metres, and is equipped with the most advanced technology.

Adhering to European quality standards, the Faberlic production facility features the most advanced and environmentally friendly equipment, automated production lines and packaging lines for cosmetic products.

Our automated production process allows us to produce high-quality products using the latest technology.

By rate of potential capacity and floor space area, the Faberlic production facility is one of the largest in Europe.

All our products undergo mandatory testing in accordance with GOST and SanPiN. The Faberlic company is listed in the state register of manufacturers of environmentally friendly and safe products.